- Resources

- White Paper

Quicker product development cycles with cellular IoT

In-Factory Profile Provisioning (IFFP) is a relatively new technology that securely inserts mobile network SIM profiles at the device manufacturing stage. Manufacturers of electronic devices can now ship their products to different destinations with cellular connectivity pre-configured for optimum coverage with the local network. You can download the In-Factory Profile Provisioning report from Transforma Insights at the bottom of the page.

Not only does In-Factory Profile Provisioning (IFFP) deliver maximum value to original equipment manufacturers (OEMs) by streamlining the assembly line production process. It also ensures out-of-the-box connectivity into each piece of hardware, with the preferred local mobile network whenever needed.

Cellular IoT devices intended for global distribution

Original equipment manufacturers (OEMs) using eSIM and IFPP can now streamline connectivity for large volumes of connected products, such as smart meters, logistics trackers, and smart wearables before they are shipped to specific global destinations. In addition, embedded SIM (eSIM) and remote SIM provisioning allow users to switch networks in the field and integrate diverse IoT applications to suit their use case.

Emerging power-constrained devices

The ability to pre-provision IoT devices in the factory mitigates network-to-device authentication in the field, which consumes battery power, reducing the ability to monitor pressure, moisture, and temperature to ensure the goods arrive in optimum condition. Configuring connectivity during device manufacturing instead of downloading the subscription profile in the field can save up to 15% of battery charge.

Improved supply chain efficiency for IoT device manufacturers

Plastic SIM cards must be manually put into each device based on the geographical destination, which is time-consuming and error-prone. Also, managing SIM inventory cards is complex, which means tracking approximately double the number of stock-keeping units (SKUs).

IFFP fast-tracks distribution logistics by removing the need to support larger SKU volumes involving physical plastic SIM cards.

Mobile network SIM profiles

eSIM remote SIM Provisioning (RSP) remotely installs, delivers and activates networks on IoT devices. The process involves attaching certificates and profiles, a combination of data and applications for the eSIM. The subscriber identity profile enables access to a specific operator network, which allows the eSIM to function on a specified local network. There are three eSIM options based on GSMA specifications depending on your deployment architecture.

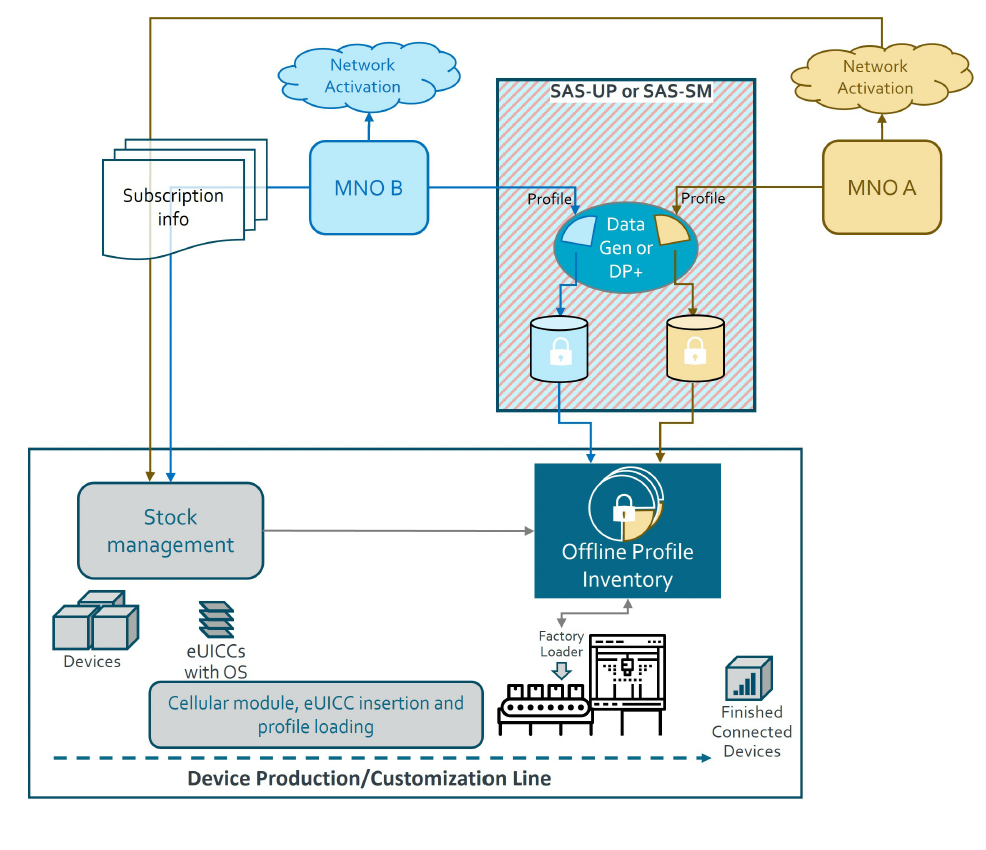

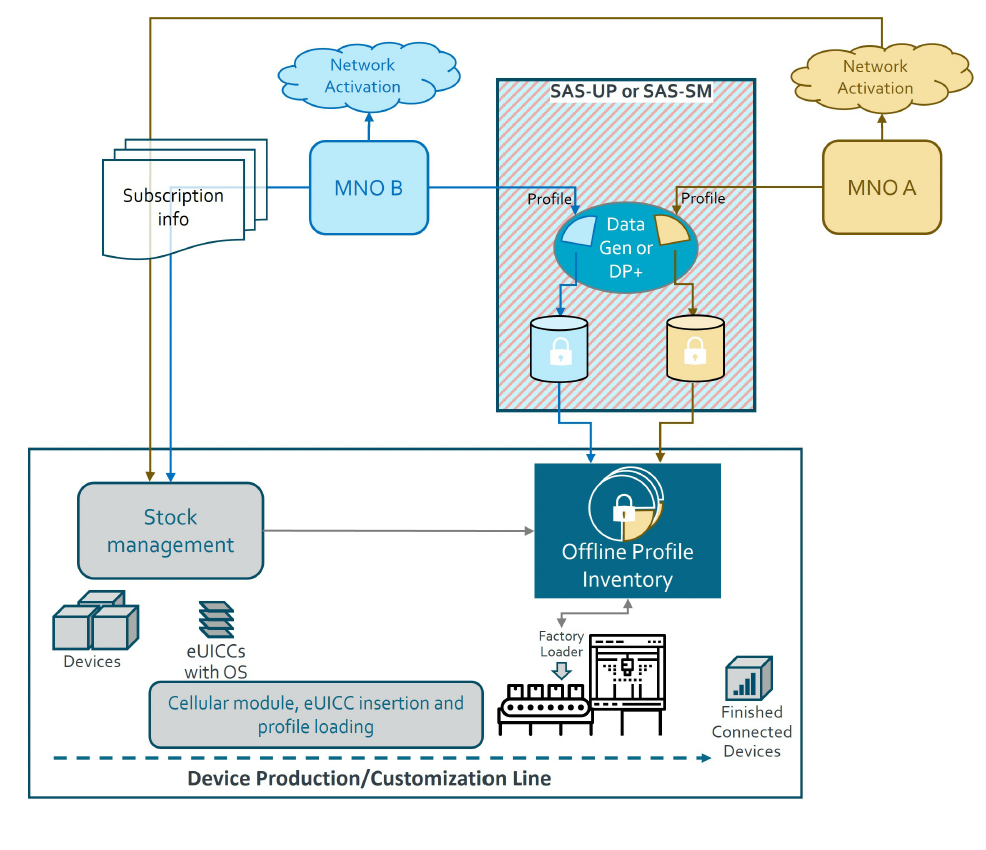

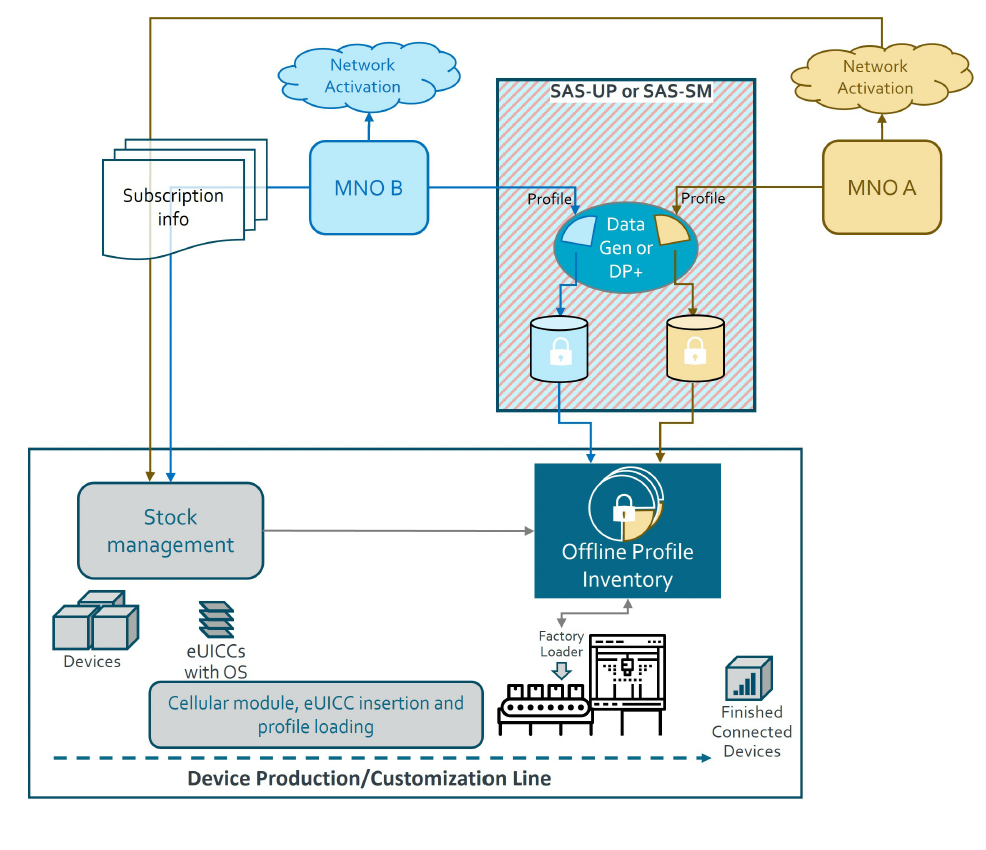

How does In-Factory Profile provisioning work?

IFFP is loaded from a digital inventory of MNO eSIM profiles to the device when the software is added or before the device is dispatched. It’s similar to eSIM RSP, where the eSIM is personalized, meaning the network operator of choice is inserted into the eSIM at the end of the device assembly process using the GSMA in-factory SGP.41/.42 specification. Subsequently, the provisioned devices can access extensive global coverage out of the box to transmit sensor data.

Moreover, loading device- and region-specific MNO profiles onto an embedded SIM (eSIM) and integrated SIM (iSIM) during device production is secure and accelerates device production leading to faster go-to-market times.

In-Factory Profile provisioning use cases

The emergence of low-power battery-powered devices means they avoid in-field provisioning where the device cycles through local networks to find the right one. Smart metering, wearables, and logistics tracking are just some of the applications that benefit from automating device configuration in the factory.

IoT device manufacturers who adopt IFFP can modify device configuration depending on their requirements, extend integration with other devices, and achieve faster device development cycles.

Want to find out how to speed up your IoT device manufacturing?

Download the Transforma Insights report below.